THE COMPANY

Founded to meet a need for products

that combine good insulation properties,

compact size, ease of installation and adaptability.

Core concept: “Thermal insulation by reflection”

Main products:

Thin reflective insulators meeting the highest standards:

Aluthermo® Quattro® (Patent application registered in 2004) Aluthermo® Optima® (Patent application registered in 2013) Aluthermo® Densima® (Patent application registered in 2013)

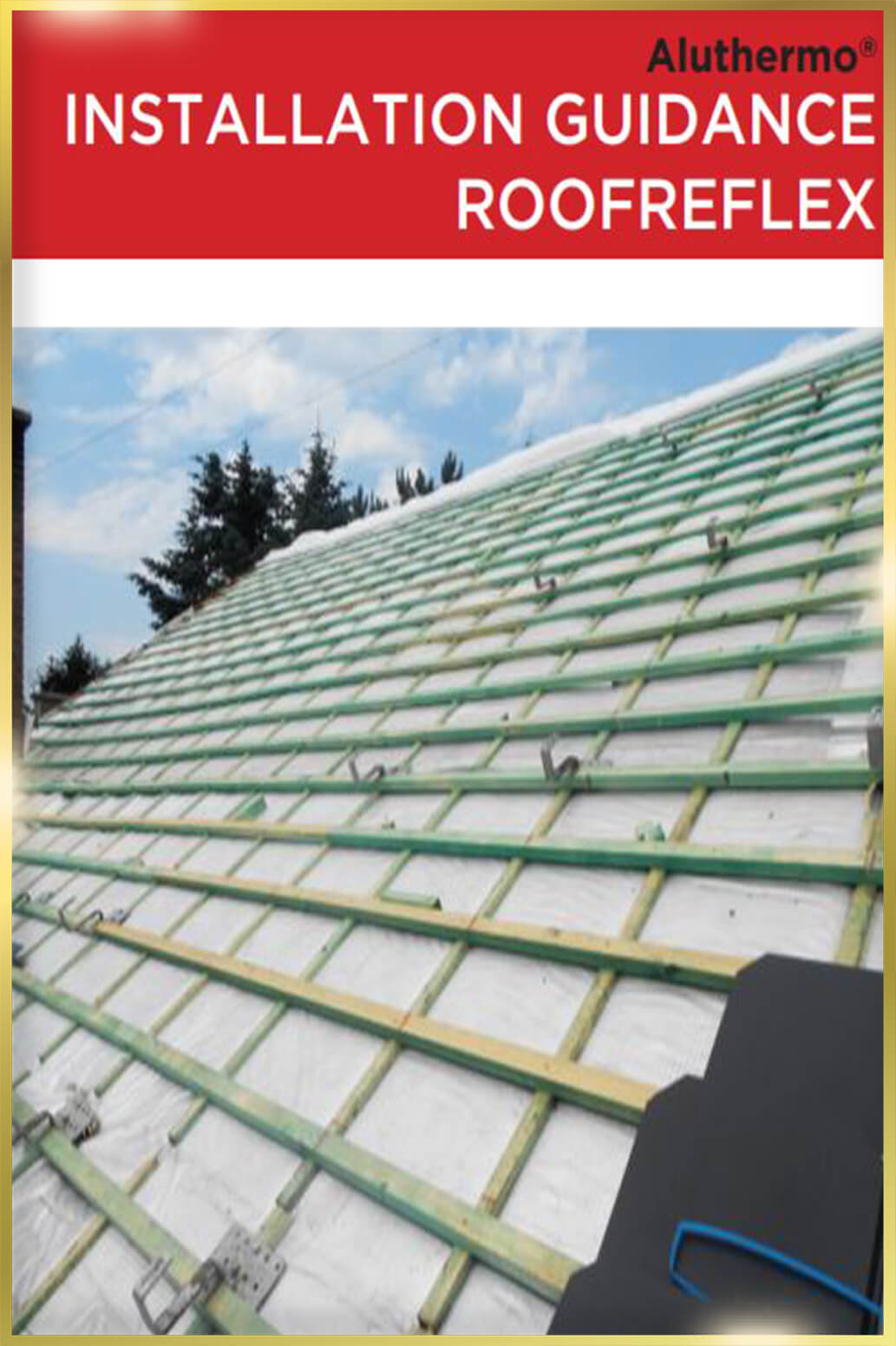

Thin reflective breather membrane: Roofreflex®

Aluthermo SA is one of the leader of the European market, with more than 15.000.000m² sold in the last years. This means more than 150.000 satisfied customers.

PRODUCT HISTORY

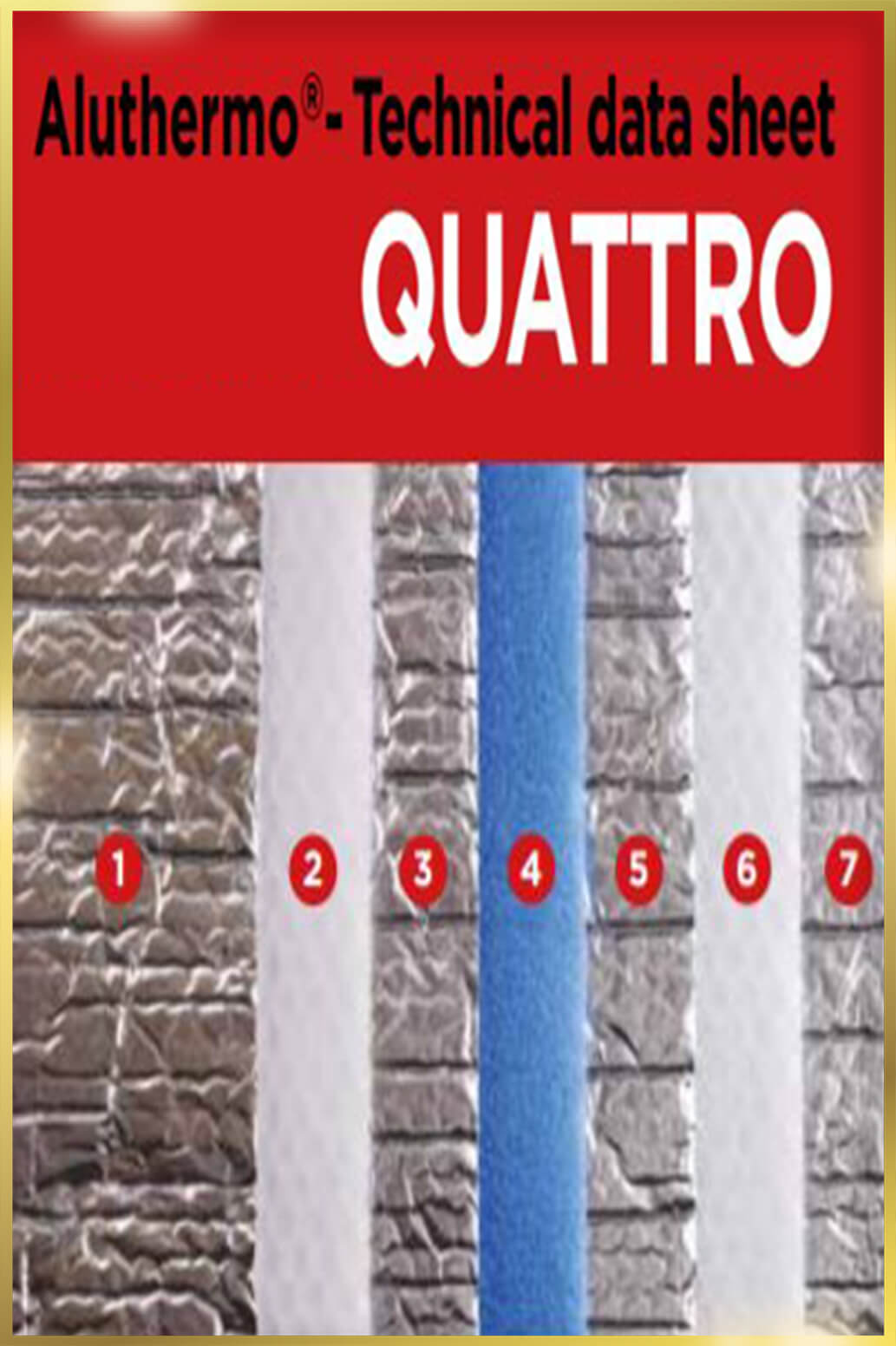

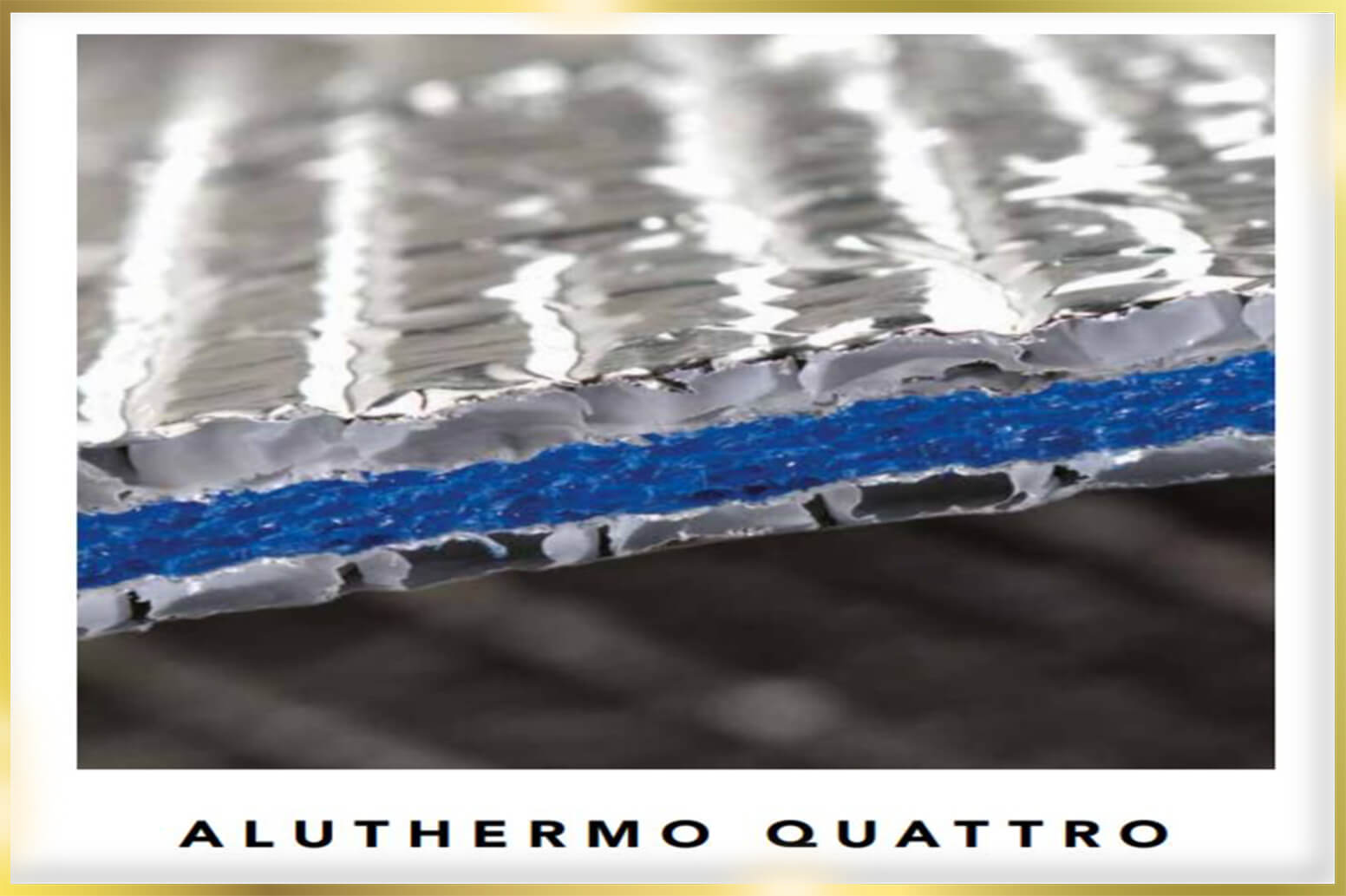

Aluthermo® Quattro – 10 mm

The first thin, multi-reflector, multi-layer insulation system with all surfaces fully thermally welded together

PRODUCT HISTORY

Aluthermo® Densima – 37 mm

Insulation, vapour barrier and breather membrane combined in one product. Made thicker to comply with European standards, it is the perfect insulation for your roof renovation.

PRODUCT HISTORY

Aluthermo® Optima – 42 mm

A Reflective insulation made thicker to comply with European standards; mainly used on roofs as vapor barrier.

PRODUCT HISTORY

Roofreflex® - 37 mm

An insulating, reflective breather membrane, highly vapor permeable.

FUNCTION

Conduction:

Transmission of heat from one body to another by direct contact

Convection:

Movement of air due to a difference in temperature

Thermal radiation:

Transmission of heat by infrared radiation without direct contact between the bodies

Humidity:

The higher the moisture content of the air, the more energy conductive it becomes.

U-VALUE

Hot box or hot plate testing:

R= δ/λ

Actual official testing method for reflective insulation (EN iso 6946=>16012) What does it mean? What are the results?

Launch of a research program on thin reflective insulation Site Test Methodology: What can we expect?

2 possible developments:

* Thin reflective insulation as a stand alone product: Aluthermo Quattro® or Densima® * Thin reflective insulation together with a complementary insulation: Aluthermo Optima® or Roofreflex®.

CERTIFICATION OF ALUTHERMO® QUATTRO

Aluthermo® Quattro: CE certified.

Declaration of performance

Following the study of the RWTH Germany, Aluthermo Quattro® achieves an equivalent thermal resistance R of 5,70 m².K/W.

Study of the RWTH

Following the Sheffield Hallam University Aluthermo Quattro® is at least equal to 200mm of Glass fibre insulation.

CIM Study

CERTIFICATION OF ALUTHERMO® DENSIMA

Aluthermo® Densima: CE certified.

Declaration of performance

Core thermal resistance:

EN12667: R = 1,02 m².K/W

Thermal resistance, installed as a breather membrane between 2 layers of air with a ventilated outer air layer and a non-ventilated inner air layer

EN16012: R = 1,77 m².K/W

CERTIFICATION OF ALUTHERMO® OPTIMA

Aluthermo® Optima®: CE certified.

Declaration of performance

Following the study of the IBP Fraunhofer Institute for Building Physics in Germany, Aluthermo Optima®, installed between 2 air gaps, has a thermal resistance of 2,37 m².K/W. (EN 16012).

Study of IBP Fraunhofer

CERTIFICATION OF ROOFREFLEX

Roofreflex®: CE certified.

Declaration of performance

Core thermal resistance:

EN12667: R = 1,00 m².K/W

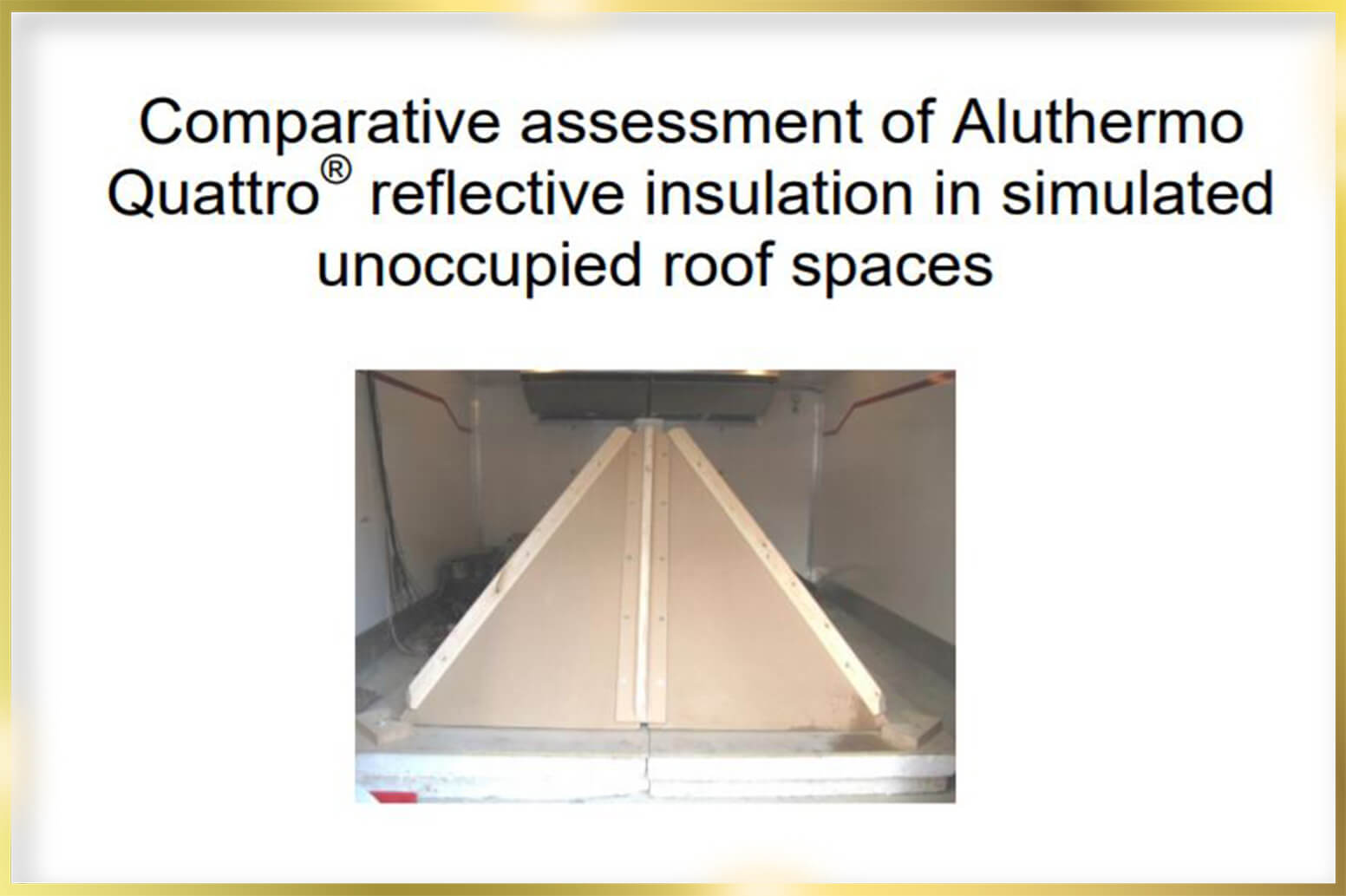

TEST RESULTS IN REALITY

A PRAGMATIC APPROACH

Unlike the measurement of loss through conduction, inapplicable to thin reflective insulation, which is expressed by the theoretical value R (thermal resistance), ALUTHERMO is focused on determining the performance of the different types of insulation in a more real base: measuring the energy consumption.

The principle is very simple: the energy necessary to maintain a reference temperature (21°C) in an insulated construction, alternatively with an insulating ALUTHERMO®and with a “classical” insulator reference in winter conditions.

Roof structure (1) alternatively insulated with Aluthermo Quattro (2), Aluthermo Optima (3), Aluthermo Densima (4) and 200mm glass wool conductivity λ 0.040 W/m.K (5).

TEST RESULTS IN REALITY

OBJECTIVE FIGURES AND CLEAR RESULTS

The structure was placed in an environmental chamber and was subject to winter temperatures of -5°C, 0°C and 5°C while maintaining within thereof a constant temperature of 21°C. The amount of energy required to maintain interior temperature was then measured and compared:

To conclude, it is clear that the thin reflective insulation Aluthermo® presents, under the actual usage conditions, higher performances than a classical insulation.

THERMOGRAPHY

Analyse of a low energy house build in Luxembourg:

> Wall insulated with 15 cm EPS

> Roof insulated with Aluthermo® Quattro

ALUTHERMO AND THE EPC

The only good approach to measure the energy efficiency of our thin, reflective insulation is by comparing the real energy consumption whereas the Energy Performance Certificate (EPC) is only a theoretical estimation of the energy requirements of a building.

ALUTHERMO® AND THE EPC: CLEAR RESULTS:

According to the new European standard EN16012, ALUTHERMO OPTIMA has a certified thermal resistance of R=2,37 m².K/W (*). That’s why we established 4 EPC certificates :

1. An EPC for the building without roof insulation. 2. An EPC with 240 MM OF CELLULOSE as roof insulation (R=6 m²K/W). 3. An EPC for the same building with only ALUTHERMO OPTIMA as roof insulation (R=2,37 m²K/W following to EN 16012). 4. An EPC for the same building where ALUTHERMO OPTIMA as roof insulation is combined with 60 MM of mineral wool.

ALUTHERMO AND THE EPC

CONCLUSION

✓ Compared to a non-insulated roof, the investment of the roof insulation with ALUTHERMO OPTIMA is paid off in about 3 years. ✓ According to the EPC, the estimated consumption of the building which was insulated with only ALUTHERMO OPTIMA, is only 7 kWh/m²/year higher than the consumption of the building which was insulated with 240 MM OF CELLULOSE. ✓ The EPC of this building achieves the same classification B with ALUTHERMO OPTIMA or a 240 MM thick insulation. ✓ According to this estimation, it fulfils to supplement with 60 MM of mineral wool to achieve the same consumption as 240 MM OF CELLULOSE as insulation.

APPLICATIONS

For the Building industry:

• Roof from outside • Roof from inside

• Walls • Flor

ROOF INSULATION FROM EXTERIOR

Advantages:

➢ Roof underlayer, insulation and vapour barrier in a single operation. ➢ The thickness and the distance between the rafters has no importance. ➢ Avoids having to demolish the interior ceiling when renovating. ➢ Does not drift and does not sag.

BE CAREFUL

Aluthermo® Quattro or Densima

ROOF INSULATION FROM EXTERIOR

Roofreflex®

ROOF INSULATION FROM INSIDE

Aluthermo® Quattro or Optima

Advantages:

➢ Insulation and vapour barrier in a single operation. ➢ The thickness and the distance between the rafters has no importance. ➢ Humidity resistant even if there is no roof underlayer. ➢ Extra height and space in your loft.

BE CAREFUL

Aluthermo® Quattro or Optima

WALL INSULATION

Aluthermo® Quattro

Advantages:

➢ Gain in habitable space. ➢ Allows the possibility of insulating walls from inside if insulation from outside is impossible. ➢ Does not drift or sag

UNDER SCREED

Aluthermo® Quattro

OTHER FLOOR APPLICATIONS

Aluthermo® Quattro

RAISED WOODEN FLOOR

EXECUTION WITH FLOOR HEATING

EXECUTION UNDER TIMBER FLOOR

➢ Very good impact sound insulation. ➢ Heat distributor. ➢ Gain in space.

OTHER INDUSTRIAL APPLICATIONS

THE SOLUTION FOR MONUMENT BUILDINGS

FRIES LANDBOUWMUSEUM - The Netherlands

ROYAL MANOR ARGENTEUIL - Belgium

HOF VAN CORTENBACH - Belgium

Aluthermo®PROVEN TECHNOLOGY

Aluthermo® – Effective, Thin, Easy to install

➢ Economical

➢ Reduced thickness

➢ Reduced weight, low storage volume, easy handling

➢ High coefficient of insulation

➢ Durable because non-rotting

➢ Waterproof

➢ No condensation

➢ No thermal bridge

➢ Acoustic attenuation

➢ Indigestible to rodents

➢ Fire classified Bs1d0

➢ Your health

➢ Easy to install

➢ 10-year warranty

➢ Recyclable

1/30

* Fire test Ghost for Russian Federation Republic * EN 13501-1 Warrington Fire

Vapour Control Test:

Vapour Control Test:

* TSUS type test repor * TSUS Test report N° 90150218 with all tested characteristics

Thermal Performance:

Thermal Performance:

*Comparative study done at CIM (UK) *Comparative study done at Eliosys (BE)

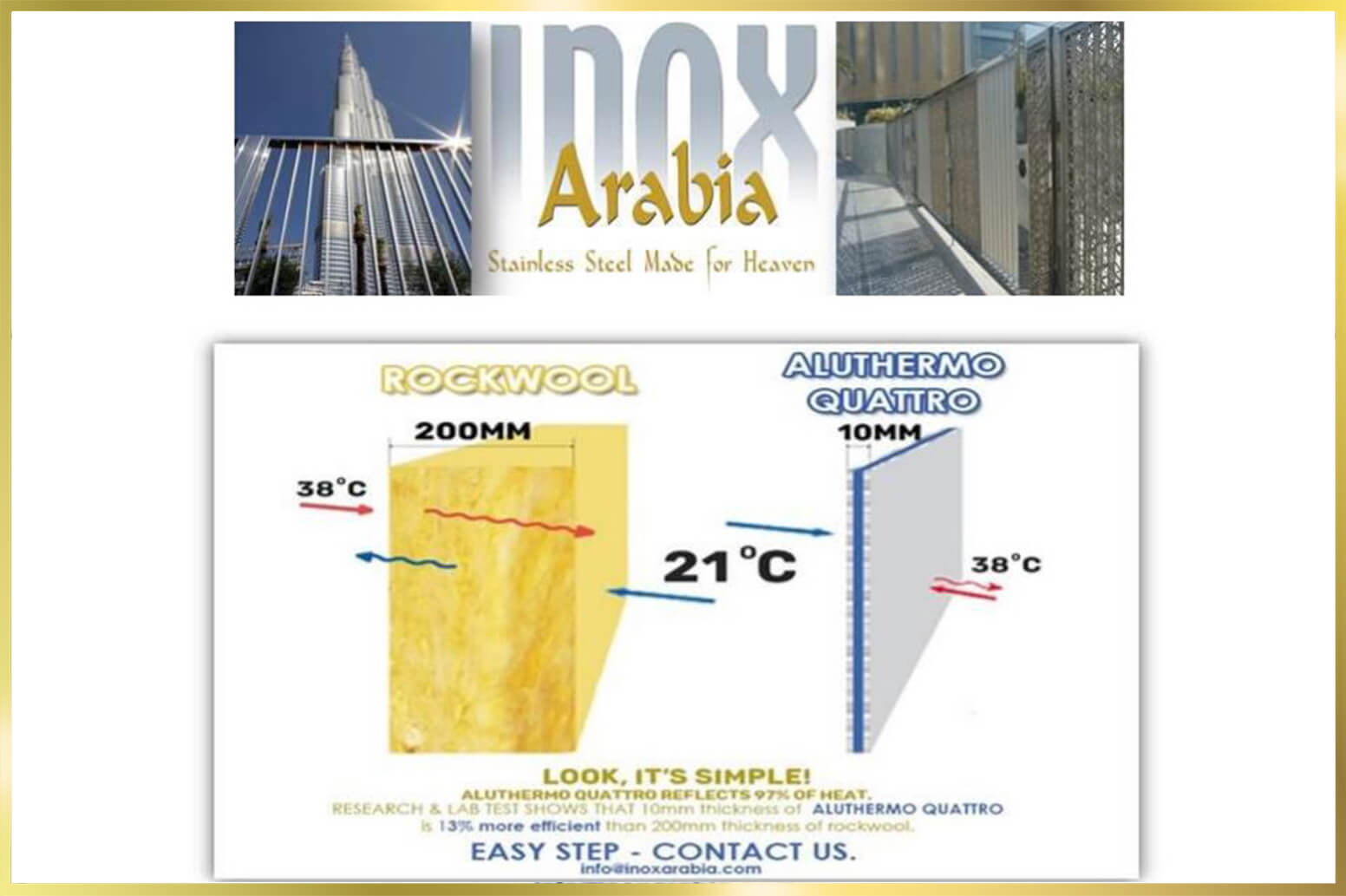

ROCKWOOL

ALUTHERMO QUATTRO

ROCKWOOL

ALUTHERMO QUATTRO

The above study shows 10mm Aluthermo Quattro is a very good thermal insulator when compared to 200mm of Rockwool. Aluthermo Quattro is having a good result is thickness, weight/sq.m, insulation, R-Value, U-Value, Thermal Conductivity (λ-Value), Humidity and Thermal Radiation. Also it is Durable & Very Easy to Install.

1/9

• A film of pure aluminium, 30 microns thick, treated against oxidation

• A layer of bubbles of dry air enclosed in self-extinguishing polyethylene

• A film of pure aluminium treated against oxidation

• A foam of fire-retarding and waterproofed polyethylene

• A film of pure aluminium treated against oxidation

• A layer of bubbles of dry air enclosed in self-extinguishing polyethylene

• Roof from outside • Roof from inside • Cladding • Interior walls • Exterior walls • Under floorboards with air gap • Under raised “floating” wooden floor • Under screed with/without floor heating • Industrial buildings • Supplementary insulation by vapour barrier

• General • Installation as Roof Insulation • Installation on walls • Installation on ceilings • Installation on floors

Water Proof & Air Tight:

• Absolute closed system is required. • Laid to full surface of the construction. • Edges of successive edges (Aluthermo) overlapped by 5 to 10 cm. • Aluthermo adhesive tape – 70 to 100 mm width (Optimal Reflection). • For perfect adhesion – must be free from dust & moisture. • A minimum air gap of 2 cm required on both sides of Aluthermo. • To provide sound proof – stretch out tight. • Air bubble protect from Crushing

1. LAYING THE ALUTHERMO:

• Unrolled horizontally over the rafters – fixed by 20 mm long staples • Next layer with overlap of 10 cm (Tile Effect) • Cover adhesive with 100 mm wide aluminium adhesive tape • Maximum rafter spacing must be 60 cm. • Stretch tight the Aluthermo and fix to the rafters.

2. BATTENS INSTALLATION

• First install the counter-battens : 40 mm thick, 4 to 5 mm width. • Must be vertical to Eaves – 80 mm twisted nails. • Lay battens to counter-battens for attaching the roofing – parallel to the eaves. • By this 2 cm air gap is obtained – assisting infrared reflection

3.INSTALLATION AT ROOF BASE:

• Unroll Aluthermo parallel to Eaves – must sufficiently overhang the wall plate. • Stretch & fix to rafters (Temporary) • Fold the sheet to wall plate & fix with staples • Seal the entire assembly with aluminium adhesive tape (Air tight)

4. INSTALLATION AT THE RIDGE:

• At the roof side the Aluthermo must cover both the sides by atleast 20 cm.

5. INSTALLATION ON GABLE:

• Fix Aluthermo to last rafter. • Fix counter-batten to gable to provide perfect air tight

6. JOINING THE SIDE WALL:

• Should be positioned to fold at least 5 cm • Fix to first rafter & press against wall by counter-batten.

7. ROOF WINDOW:

• Draw the frame on Aluthermo & cut along the 2 diagonals. • Fasten Aluthermo with wooden frame – folding 5 cm from top of the frame. • Cut off excess insulation & put special adhesive tape on corners & edges.

8. JOINTS AT VENTS & AERIALS ETC.,:

• Draw the location on Aluthermo. • Cut in 2 diagonals. • Fold back the Aluthermo & bond the edges with adhesive tape.

9. CHIMNEY JOINT:

• If exterior temperature exceeds over 90 degree – do not lay insulation close to 20 cm. • Remaining filled with Non-combustible insulating material. (French category “MO”).

ROOF INSTALLATION WITH LATH DECK OF EXPOSED BEAM

• Construct a batten frame on top of lath deck – to create air gap. • This frame is formed by criss-cross battening. • Nail measuring minimum 30 mm battens & 50 mm to rafters. • Then lay the Aluthermo as same procedure – without lath deck. • Use staples at every 5 cm. Seal the joints with special adhesive tape. • Now fasten with second level of battens with vertical & horizontal battens for attaching the roofing.

ROOF INSTALLATION FROM INTERIOR

ROOF INSTALLATION FROM INTERIOR

• Unroll the sheet parallel to the rafters. • Fasten to the rafters by 5 cm turn-down. • Then stretch the Aluthermo - staple them to rafters & purlins at max. 20 cm between staples. • Next sheet must be minimum of 5 cm overlap and fix with adhesive tape. • Fasten the last plate to the wall plate – staple every 5 cm. • Then fasten the lath to the rafters. This will press the Aluthermo against the purlins.

INSTALLATION ON WALLS

1. EXTERIOR WALL INSULATION:

• Fasten the framework of laths measuring 30 * 50 mm against the wall to be insulated. • The vertical laths must be spaced approximately 60 cm. • This provides stable air gap between the wall & Aluthermo. • Unroll the Aluthermo horizontally over the framework – minimum overlap 5 cm. • Seal the overlap by special adhesive tape. • Then fasten the counter-laths to framework for final metal or timber cladding.

2. INTERIOR WALL INSULATION:

• Aluthermo can be installed vertically or horizontally with minimum overlap of 5 cm. • The frame work of lath dimension 25 * 50 mm is made to the wall interior. • Seal the overlap with special adhesive tape. • The vertical lath must be spaced approximately 60 cm. This provides uniform air gap. • Then fasten the counter-laths to the framework of interior finish.

CONCREATE CEILING INSULATION

• Follow the same instructions as that of interior wall insulation

INSTALLATION UNDER FLOOR BOARDS

• Unroll the Aluthermo and fix them to the bottom timber frame. • Cover the overlaps with the adhesive tape (Min. 5 cm overlap). • Then screw the laths measuring 3 * 5 cm wooden floor beams. • Fasten wooden or particle board flooring over this.

If Insulation laid on Concreate Floor:

• Form a lath layer above the concreate floor. • Fasten the Aluthermo over this layer with minimum overlap of 5 cm. • Cover the overlap with special adhesive tape. • Lay the counter-batten over this and screw them. • Fasten the flooring over this.

INSULATION UNDER FLOATING FLOOR

• Make sure the structural floor is smooth. • If necessary install a layer of plastic foam before laying the Aluthermo. • Spread the Aluthermo folding it up along the adjacent walls. • Do not overlap the strips. Lay them edge to edge, sealing with adhesive tape. • Then install a layer of particle board before fitting the floating floor.

INSULATION UNDER SCREED

• Make sure the structural floor is clean & smooth. • If necessary make a plastic foam before Aluthermo sheet. • Lay the Aluthermo sheet, folding up along the adjacent walls. • Do not overlap the sheets. Lay edge to edge & put the adhesive tape. • Plastic sheet is absolute necessary to be laid over the Aluthermo layer. • Then install mesh and screed

INSTALLATION WITH UNDER-FLOOR HEATING

• Make sure the structural floor is smooth and clean. • Lay a plastic foam before laying the Aluthermo. • Spread out, folding up along the adjacent wall. • Do not overlap. Put the adhesive tape at the joints. • A plastic layer must be laid above the Aluthermo before installing the hot water pipes. • Then lay the screed.

1/29